4 Steps of Joining 2 Peices of Clay Togrther in Intro to Art

BASICS

Dirt is an bawdy material of fine grained minerals with traces of metal oxides and organic matter.

Pottery tin be created without the use of a potter's wheel. The potter's cycle did non appear in history until only iv 000 years agone. The primary construction methods were compression and coil methods.

Clay has been used for many things throughout homo history: a writing surface, building material, money, storage containers, cooking vessels and serving plates, electronic device parts, ceramic shields or tiles are used on space ships. Ceramics is a major tool for dating cultures in archeology studies.

the three hand-edifice techniques

pinch

Compression pots are created past using your hands to shape the clay. Pinch pots are some of the oldest archaeological artifacts found on the planet.

- Brainstorm past forming a smoothen ball that fits in your palm (fist size).

- Press the thumb into the middle one-half-fashion to the lesser.

- Circumduct the ball while pressing the walls out evenly with the other hand.

coil

Coil pots are created past pressing coils of dirt together.

- Keeping the fingers flat, course clay into sausage shapes.

- Roll them into ropes (coils)

1/four" to 1/two" thick - Coils are pressed together creating a design. Gaps are filled in with small-scale balls of clay.

- Inside of the wall tin be smoothed.

- Join the walls & the bottom.

slab

The slab building technique involves rolling out clay to an even thickness - usually 1 cm - then cutting shapes, folding, angle, manipulating and joining together to grade a finished object.

- Roll slabs of clay

- Cutting out the sides

- Join the sides (score and slip!!)

- Attach the bottom

- Cut out the excess clay from the bottom slab.

Other techniques include:

wheel throwing, relief (high, depression, sunken), mold making & slip casting, carving, sculpting, etc.

(remove air bubbles)

throw

wedge

beat to course a ball

drying stages of clay

slip

(liquid course of clay)

casting and cementing pieces

plastic

wedging, manipulating, sculpting,

throwing on the bike...

leather difficult

almost decorating is done, carving, stamping, building, etc..

os dry

the driest phase of dirt, 0% wet, ready for bisque firing

firing stages

greenware

unfired pottery that is bone dry (about frail state)

bisqueware (bisque)

unglazed pottery that has been

fired once

glazeware

ware that has coat applied and is waiting to exist glaze fired

joining pieces

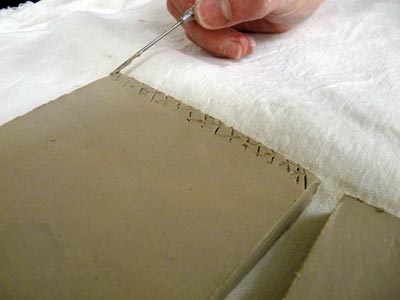

1. score

Roughen both surfaces that you are joining. Use a cantankerous-hatching pattern. Use a needle tool, wedge tool with "teeth", etc.

ii. slip

Apply enough skid to both surfaces. Slip will "cement" the pieces together equally a mucilage.

3. rock & press

Stone back and along while applying some pressure on the slice. This will ensure that the slip will fill in all gaps and removes air pockets.

tools

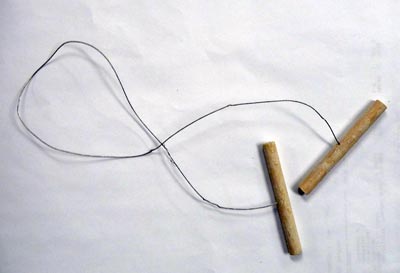

cut-off wire

needle tool and fettling knife

modeling tools

rolling pin and guides

drying

Clay project should dry for at least 7 days earlier bisque firing to ensure information technology does not blow upwards in the kiln.

Moisture (sudden change of water into steam) and air bubbles (trapped air expands) tin can cause the explosion.

firing

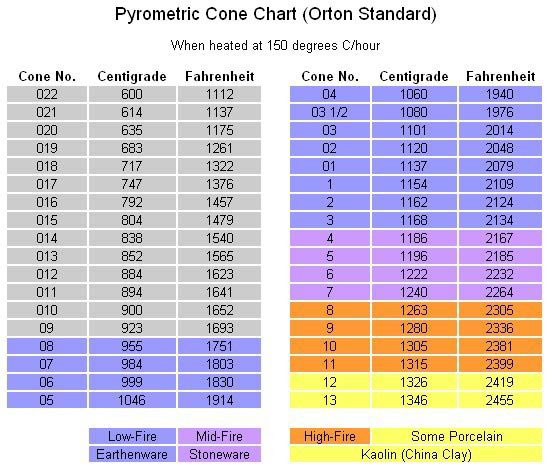

bisque firing

we use low-fire dirt

Cone 04

Temperature 1940 F

glaze firing

we employ by and large low-fire glazes

Cone 05-06

Temperature 1830-1914 F

glazing

- utilise at least 3 coats

- employ coats evenly, wait for a coat to dry out earlier applying the adjacent one

- do not apply glaze on a bottom surface - the 1 that will be in contact with the kiln's shelf.

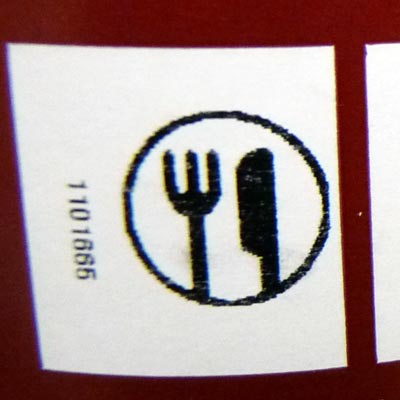

wipe information technology clean with a wet sponge before turning in for glaze firing - if your finished piece will be in contact with food - look for food safe marking on a glaze jar.

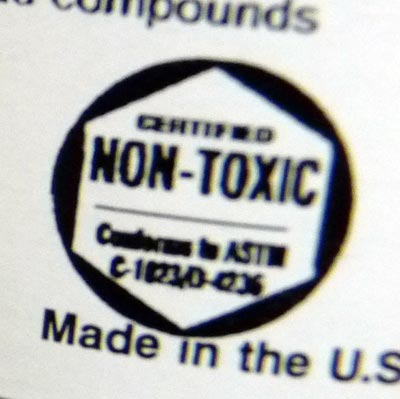

All glazes that are rubber for nutrient contact are labeled with one of the following signs:

the ten gilt rules of ceramics

- Clay must be thoroughly covered upwardly with a plastic bag to go along it from drying out. This applies to works in process and moist clay.

- Clay dust can be harmful if you are exposed to it for long periods of time, then keep your area clean, dirt scraps off the floor and clean with water and sponge.

- Clay should be no thicker than your thumb.

- In guild for clay to stick together it must exist scored and and slipped together while the clay is moist (plastic) or leather hard.

- Wedge dirt to remove air bubbling, reach uniform consistency, and to line up the clay particles.

- Trapped air can cause dirt to explode. And then hollow out sculptural forms and put needle holes through enclosed forms for air to escape.

- Don't glaze the bottom of the piece.

- Wash the piece before glazing.

- Handle your project with two hands at all times. In other words - be careful! - it's your hard work.

- NEVER handle another person's work fifty-fifty if it looks cool!

Source: https://juliannakunstler.com/ceramics1.php

0 Response to "4 Steps of Joining 2 Peices of Clay Togrther in Intro to Art"

Enviar um comentário